Are you ready to dive into the fascinating world of liquid silicone molding process? This cutting-edge technology has been transforming the manufacturing industry, offering numerous advantages and possibilities. Let’s explore this innovative process together!

The Basics of Liquid Silicone Molding Process

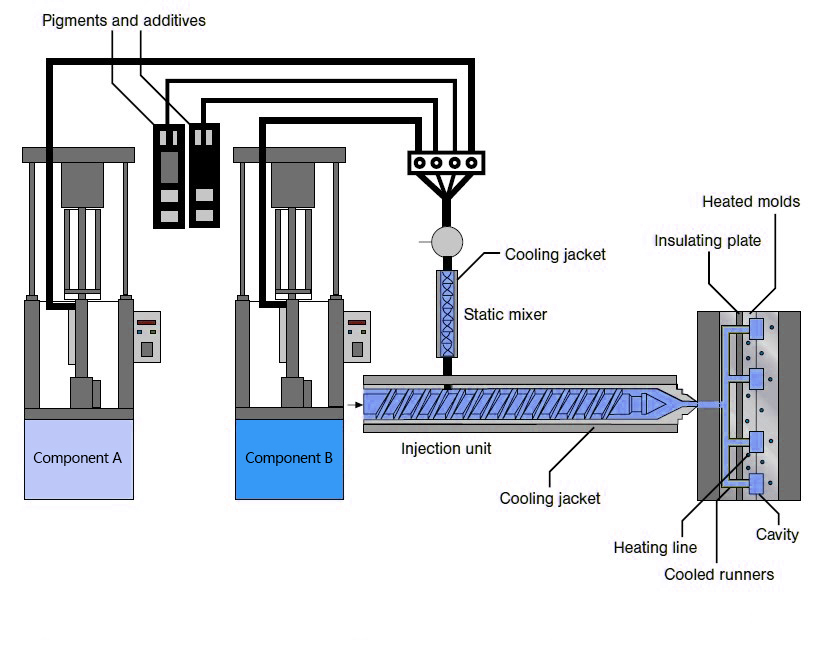

Liquid silicone molding process is a technique that involves injecting liquid silicone rubber into a mold cavity and allowing it to cure. This method enables manufacturers to create complex shapes with precision and consistency. The liquid silicone material offers excellent flexibility, durability, and heat resistance, making it ideal for various applications.

Introducing JVTECH: A Leader in Liquid Silicone Molding

When it comes to expertise in liquid silicone molding process, one name stands out – JVTECH. With years of experience and state-of-the-art facilities, JVTECH has become a trusted partner for companies seeking high-quality molded products. Their advanced machinery ensures efficient production while maintaining strict quality control standards.

Molding Toys: A World of Creativity

The versatility of the liquid silicone molding process opens up endless possibilities in toy manufacturing. From intricate details on action figures to soft yet durable components for plush toys, this technology allows designers to bring their imagination to life. Moreover, the use of non-toxic materials ensures safe playtime for children.

Click molding toys.

In Conclusion

The liquid silicone molding process revolutionizes manufacturing by providing unparalleled precision and efficiency. Whether it’s producing medical devices or creating customized consumer products like toys or kitchenware, this technology offers immense potential for innovation across industries. Embracing this cutting-edge technique can lead businesses towards success in today’s competitive market.